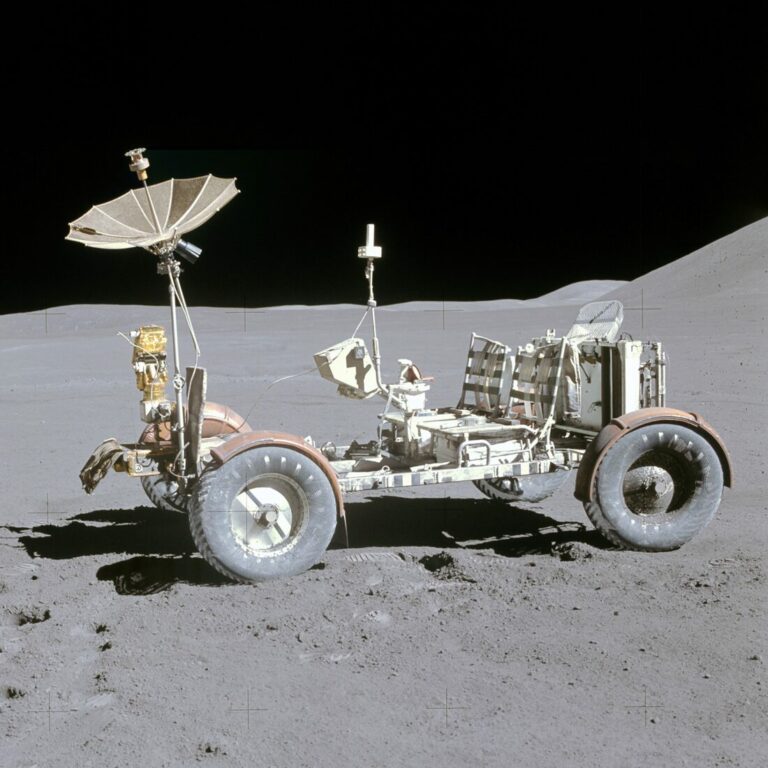

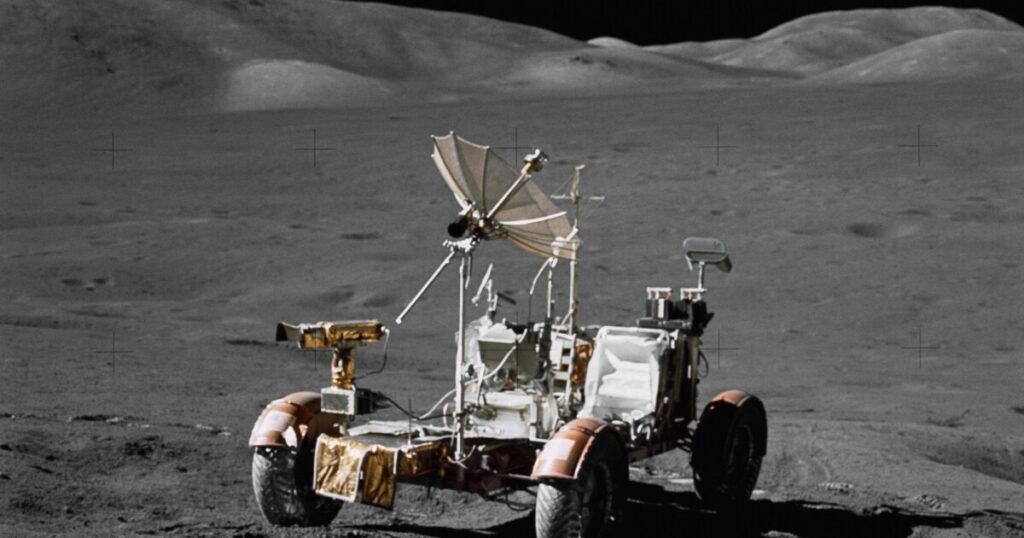

It’s a small car, light, foldable, almost rustic, and yet it laid the foundation stone for what may be the Moon’s future energy economy. With its elementary electrical architecture and non-rechargeable silver-zinc batteries, the Lunar Roving Vehicle (LRV) of the Apollo missions acted as an open-air laboratory (no pun intended) to answer a question that is now obsessing space agencies and industry alike: what does a battery look like that has to survive where nothing is done for it? By analysing this rover, which took 17 months to design and three of which were abandoned on site, we discover that the story of the first lunar electric vehicle may also be the story of the future energy standards of the lunar economy.

The LRV becomes an energy matrix

When NASA approved the project in 1969, it didn’t order a futuristic vehicle, but a vehicle used as a scientific consumable: a tool that could open like a deckchair, support two astronauts and extend the exploration radius. Boeing and Delco have 17 months to deliver a vehicle that is 100% electric, 100% reliable and 100% expendable. The result was a tubular platform weighing 210 kg that could be folded up, made functional and designed to be abandoned in situ. In other words, a technical manifesto on how to think about maintenance-free energy.

You have to visualise it: no recharging possible on the Moon, no infrastructure, no on-board solar panel, no emergency module. Only two 36 V silver-zinc batteries, irreversible, sealed, designed to deliver a single life cycle: 121 Ah each, i.e. 242 Ah for the whole system. In an environment where temperatures range from +120°C to -155°C, with an absolute vacuum and abrasive dust, these batteries were expected to last a theoretical 57 km, far longer than the distances actually covered.

Managing energy as a commodity

The LRV was conceived as a project for maximum energy sobriety. Not out of militancy, but out of necessity. Every available watt had to be invested in movement, steering, cameras and communication. Nothing superfluous, no luxurious redundancies, no power-hungry electronics. This architecture sets a fundamental precedent, and one that could resonate with manufacturers: on the Moon, energy is not a flow, but a stock. As long as there is no recharging infrastructure, a lunar vehicle will operate in a disposable battery economy, where the battery is no longer a mobility consumable but a logistical asset.

This model alone prefigures the energy economy of lunar bases: before solar stations, thermal storage or regenerative fuel cells are built, the first constraint will be the cost per kilowatt-hour delivered from Earth. For Apollo, each silver-zinc battery was expensive, weighed a lot, took up a lot of space in the lunar module and had only one useful life. Today, when rover concepts (GM, JAXA-Toyota, Intuitive Machines) envisage longer missions and shared platforms, it is still this logic inherited from the LRV that predominates: no robotic or manned mission can afford to consume too much energy.

Thermally fragile, mechanically robust

The LRV’s silver-zinc batteries did more than just power four 190 W motors. Above all, they served as a full-scale test to understand the challenges of storing energy in an environment where heat does not dissipate. Where the cold penetrates everything, and where there is no convection to balance the temperatures. The system included wax boxes, multiple insulators and strict compartmentalisation to keep the chemistry within a narrow range.

And this is undoubtedly where the great industrial lesson of Apollo lies: even with a simple, robust vehicle that has no recharging, temperature control represents a major energy cost. On future rovers, which will be recharged using solar panels, rebuildable batteries or exchangeable batteries, it will always be thermal management that determines real efficiency. Lunar energy savings therefore depend not only on the density of the batteries, but also on their ability to withstand the lunar climate.

A 4×4 that foreshadows the logic of energy redundancy

Each wheel on the LRV had its own motor, its own gear train and its own brake. This choice was not a luxury: it was a way of creating a vehicle whose propulsion could not suffer a ‘single point of failure’. From an economic point of view, this means that a mission must maximise battery efficiency while minimising the risk of immobilising failure.

This principle of energy modularity, i.e. several small motors rather than one large one, several small loads rather than a single one, can be found today in contemporary projects. GM, for example, is planning a rover in which each engine module and each battery segment is interchangeable. Toyota-JAXA is planning an architecture where entire packs will be replaced by logistics robots. The Apollo philosophy is back with a vengeance: on the Moon, reliability has more economic value than raw performance.

The true legacy of the LRV

The Apollo rover could have travelled 57 km. It never did. NASA imposed a rule: never go further than the distance you could walk back if your battery ran out. This limit, often forgotten, is the first lunar energy ‘regulation’: a trade-off between potential autonomy and safety. Now that we are talking about semi-autonomous rovers capable of exploring remote regions, this constraint is reappearing in another form: a lunar base will only be able to extend as far as the energy available for exploration, maintenance and return allows. The lunar economy will therefore be centred on a simple idea: mobility will depend on local energy sovereignty.

The three Apollo rovers are still on the Moon. Their silver-zinc batteries are empty, cold and probably cracked, but they bear witness to a fundamental fact: the Moon is an environment where nothing is automatically recycled. Every kilogram of battery becomes a strategic waste. The LRV shows us that dependence on batteries is a lock, but also an incentive to invent closed cycles: interchangeable packs, robotic energy depots, roving solar recharging stations, micro-grids between habitats. In other words: Apollo showed the constraint. The 21st century will have to invent the ecosystem.

Thinking about the future lunar economy

The Lunar Roving Vehicle was not a mobile laboratory. Yet that’s exactly what it has become: an unwitting prototype of the lunar battery economy. Its limited energy, modular architecture, improvised cooling, limited theoretical range, disposable batteries and abandonment in situ form a matrix that today’s manufacturers are still trying to solve. At a time when GM, Toyota, JAXA, Lockheed Martin and others are imagining lunar mobility services, shared rovers, logistics platforms and even « regolith taxis », Apollo’s little vehicle reminds them of an essential truth: on the Moon, the first scarce resource is not water, metals or helium-3, but usable energy. And up there, every economy starts with a battery.

Sources: Wikipedia – www.fst.com – www.evokemotorcycles.com – www.nasa.gov