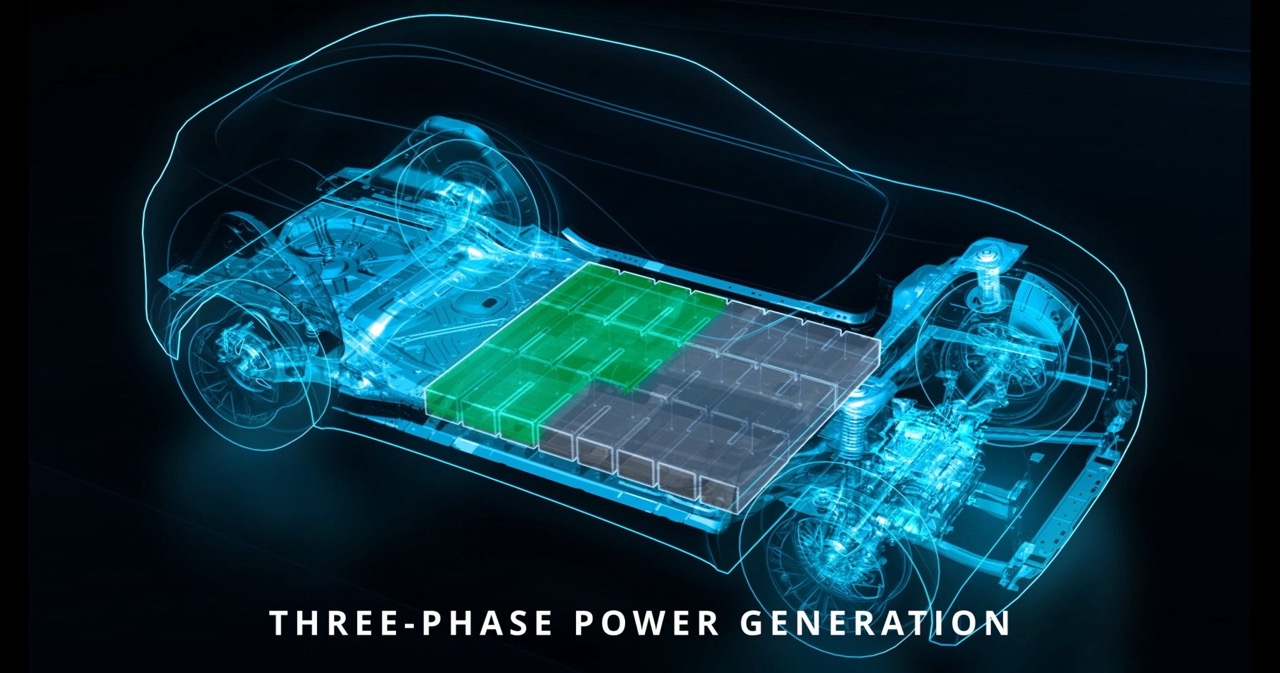

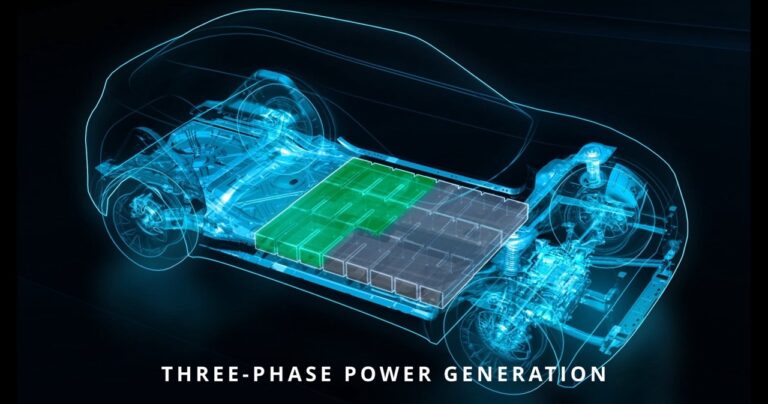

While the issue of batteries for electric cars remains central, Stellantis unveiled its new battery prototype in September, a technology called IBIS (Intelligent Battery Integrated System). The aim is to make tomorrow’s cars simpler, lighter and, of course, more efficient.

A simplified, more efficient battery

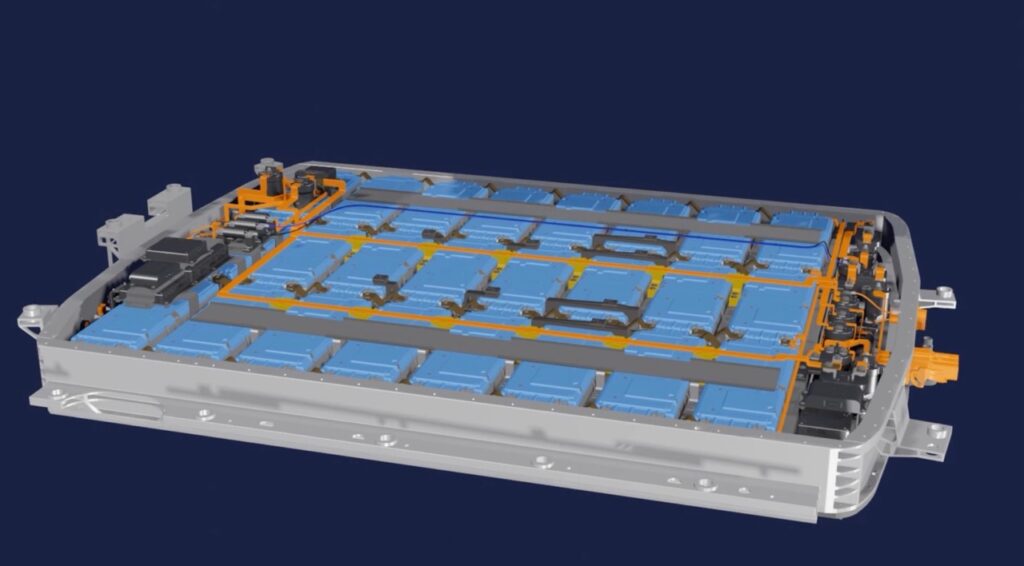

Designed in partnership with Saft, a subsidiary of TotalEnergies, this innovation is currently being tested on a prototype Peugeot e-3008. Unlike conventional batteries, where the inverter and charger are independent components of the battery, the IBIS prototype integrates them directly into the battery pack. This combination delivers a 10% gain in energy efficiency, reduces the vehicle’s weight by 40 kg and frees up 17 litres of extra space. Based on initial results, the Stellantis Group has announced that recharging times could also be reduced by around 15%, i.e. one hour less than a standard AC recharge.

Challenges to solve

While this project looks convincing on paper, there are still some questions to be answered. With so many components in the same block, there is the question of how to manage the heat generated. Another challenge is to move from prototype to industrial production, a costly and complex stage, even if the Group can rely on its European battery production partners to support them in this probable ramp-up.

A future yet to be written

While Stellantis plans to test these batteries in a demonstration fleet as early as 2026, we will have to wait until the end of the decade to see them developed in series.

With IBIS, Stellantis hopes to catch up with Asian giants BYD and CATL, who still largely dominate the sector.